|

The Stevens family are well remembered for

their vehicle manufacturing company A.J.S. but the less

glamorous Stevens Screw Company has almost been forgotten. Both

companies have the same roots and their histories are entwined.

It all started in 1874 when Joseph Stevens

founded J. Stevens & Company in Cross Street, Wednesfield. He

was an engineering blacksmith who not only did the traditional

work of horse shoeing and making parts for harnesses and bridles

but also repaired all kinds of things. He could turn his hand to

almost anything and repaired all kinds of metal equipment,

wheelbarrows, garden tools, bicycles and did work for the lock

trade, which was booming in those days. When old enough, his

eldest son Harry joined the business and quickly became

proficient. He was a fast learner and soon began producing

special purpose machine tools for the lock trade.

In 1894 the business moved to Tempest

Street in the centre of Wolverhampton and Harry and his father

were joined Harry’s younger brother Joe. An American “Mitchell”

single cylinder four stroke petrol engine was purchased to

provide the draught for the hearth, but it was unreliable and a

poor performer. Harry being dissatisfied with its performance

decided to build his own. It was completed towards the end of

1897 and worked extremely well producing 1.75h.p.

Harry and his father were quick to

recognise the huge potential market that existed for petrol

engines to power all kinds of machinery and so in 1899 they

formed the Stevens Motor Manufacturing Company alongside the

existing J. Stevens & Company.

|

|

Harry's first motorcycle using the

'Mitchell' engine.

|

Around this time Harry turned his attention to a

motor powered cycle. He fitted the “Mitchell” engine to an old

B.S.A. bicycle that had been lying in the works, and apart from

the temperamental engine it was a great success. At the time J.

Stevens & Company were making spokes and screws for the

successful Wearwell Cycle Company of Wolverhampton. William

Clarke who ran the company was keen to produce a motorised

machine. |

| He was interested in Harry’s prototype and soon

a contract was drawn up between Wearwell and the Stevens Motor

Manufacturing Company for the production of a suitable engine.

The contract assured a regular order for engines and the first

Wearwell-Stevens machines appeared in 1901.

The new machine was a great success and a range of Stevens

engines were developed. Larger premises were soon necessary and

so in February 1904 the Tempest Street premises were vacated in

favour of a larger site in Pelham Street. Later that year the

decision was taken to form a Limited Company to encompass the

interests of both the Stevens Motor Manufacturing Company and J.

Stevens and Company. The new Company, known as the Stevens Motor

Manufacturing Company Limited was registered on 10th

December, 1904 with a maximum share capital of £5,000. The

shareholders were Joseph Stevens Snr.; W. Barnett, a partner

with Joseph Stevens in J. Stevens & Co.; Harry Stevens; W.H.

Haden, gentleman; George Stevens; T.E. Lowe, accountant and

F.R.W. Haywood, solicitor. The Company Directors were Joseph

Stevens Snr., W. Barnett and W.H. Haden.

Although things initially went very well for the new company,

a reduction in sales led to financial difficulties during the

summer of 1905. In order to safeguard the screw, rivet and small

turned parts side of the business, a new company, The Stevens

Screw Company Limited was formed early in 1906 and premises were

acquired in Retreat Street. The company was run by Joseph

Stevens Snr. and his daughters Lily and Daisy. |

| Key to the map:

Number 1 = Original

Steven's Screw Company Limited's site stretching from Retreat

Street to the Penn Road with the two houses at the rear.

Number 2 = Premises

brought by the Stevens Brothers and occupied by A.J.S., Stevens

Brothers (Wolverhampton) Limited and Stevens Screw Company.

Number 3 = Premises

rented by Stevens Brothers (Wolverhampton) Limited from 1933 to

about 1956. |

| The location of the

family's premises in Retreat Street. |

|

|

About half a dozen people were employed in

the new factory producing small turned studs, rivets and screws,

mainly for the lock trade. Another speciality was screwed

engineer’s studs. Business grew and 2 or 3 years later several

new machines were installed to make small repetition parts.

There were two factory buildings made of wood and a brick built

office building. They are not shown on the 1903 Ordnance Survey

map and so must have been nearly new when the company moved in.

At the front in Retreat Street was the

largest factory building, the Capstan Shop, with the office

above. Below the office, in the centre, was a large doorway that

gave vehicles direct access into the works. On one side of the

doorway were the stores and the cleansing room. Behind the

Capstan Shop was the Screw Shop where the screw studs and lock

studs were made and behind this facing on to Penn Road were two

houses that were occupied at one time or another by family

members. Joseph Stevens Snr. and his family occupied one of them

in the early years.

The screws, nuts and bolts were made from

bar on capstans and the lock studs were turned on machines that

were designed by Harry Stevens using a revolving dye head. They

were a great success and in use for many years. In the cleansing

room the products were cleaned in paraffin and sieved to remove

any swarf etc.

|

| The premises on the

corner of Retreat Street and Penn Street that was

purchased by the Stevens brothers. Courtesy of the late Geoff

Stevens. |

|

In 1909 Joseph’s 4 eldest sons, Harry, George

Joseph and Albert John also moved into Retreat Street in

premises across the road. They had recently founded a new

company called A.J. Stevens & Company Limited and acquired the

premises to manufacture motorcycles. The new machines

manufactured under the name of A.J.S. were extremely successful

and orders flooded in. By 1915 larger premises were essential

and the brothers purchased Graiseley House and the surrounding

land on which to build a new factory. |

| They left Retreat Street in 1917 and allowed the

Stevens Screw Company to use their building for additional

workshop space.

Joseph Stevens youngest son Billie joined-up after the outset

of the war and saw service in Salonika and the Dardanelles. When

he returned home his father immediately appointed him as a

director of the Stevens Screw Company Limited and his brothers

offered him a managerial post at A.J.S. in charge of spares and

the export department.

|

|

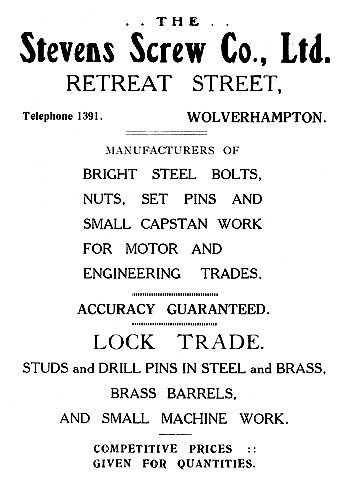

An advert from 1929. |

The late 1920s and early 1930s was a bad

time for vehicle manufacturers due to the recession. At A.J.S.

sales declined and the company went into voluntary liquidation

in 1931.

The following year the five Stevens brothers formed a

new company, Stevens Brothers (Wolverhampton) Limited and moved

back into their premises on the corner of Retreat Street and

Penn Street.

During the next few years they manufactured a

three-wheeled van and Stevens motorcycles. Van production ended

in 1936 and motorcycles were built until 1938 when the company

decided to concentrate on general engineering. During the war

they manufactured and machined components for most of the

leading aircraft companies and were sole manufacturers of the

torpedo setting gear for the Fairey Swordfish torpedo bombers. |

| By the late 1930s age was catching up with

Joseph Stevens Snr. and his youngest son Billie took over the

running of the Stevens Screw Company Limited. In 1938 his son

Jim started work at Stevens Brothers. |

The Directors of the Stevens Screw Company

Limited in 1948. Courtesy of Jim Stevens. |

Standing Left to Right:

Daisy Jones daughter of Lucy Stevens, William Stevens (Billie),

William Simpson who was married to Ethel Stevens, and Gladys

Barrett - Daisy Jones' sister.

Seated Left to Right:

Lily Wood née Stevens, Daisy Weir née Stevens. |

Standing Left to Right:

Daisy Jones daughter of Lucy Stevens, Freddie Hunting who was in

charge of the Capstan Shop, William Stevens (Billie), Jack

Hunting (son of Freddie) who was in charge of the Screw Shop,

Horace Bowdler - Works Manager, William Simpson who was married

to Ethel Stevens, and Gladys Barrett - Daisy Jones' sister.

Seated Left to Right:

Lily Wood née Stevens, Daisy Weir née Stevens.

|

The Directors and key staff of the Stevens

Screw

Company Limited in 1948. Courtesy of Jim Stevens. |

|

An advert from 1951. |

The Stevens Screw Company Limited continued to be

successful and by the early 1950s there were over 70 staff.

Production consisted of hundreds of different small parts

including bolts, nuts and screws in ferrous and non-ferrous

metals made from the bar.

They were supplied to the motor,

cycle, electrical, general engineering and lock trades. Many of

the customers purchased components for export. Most of the

workforce was female apart from the male setters. |

|

In 1956 Jim Stevens was appointed a

director of Stevens Screw Company Limited following the death of

his father Billie and was made responsible for running the

company. The decision was made to sell Stevens Brothers

(Wolverhampton) Limited, his father and uncles having died, and

to concentrate on the running of the screw company.

The main customer at the time was Wilkins

and Mitchell Limited of Darlaston and many of the Stevens’

components found their way into Wilkins and Mitchell’s ‘Servis’

washing machines. Other important customers were Rothley Brass

who manufactured brass door fittings and bathroom fittings; and

the Moss Gear Company.

By the 1970s most of the screw company’s

customers had gone into liquidation and the company slimmed down

considerably. Jim Steven’s was responsible for running the works

and his wife Joan the office.

|

An advert from 1953.

|

|

An advert from 1958.

|

Most of the shareholders were family

members who used to work for the company and had now retired.

After the company’s A.G.M. in 1973 their accountant suggested

that Jim and Joan should buy the other shareholders out and this

they did forming a new company called The Stevens Screw Company

(no longer a Limited company).

A little while later Wolverhampton Council

served a Compulsory Purchase Order on the old buildings which

were to be demolished to make way for a new car park for the

nearby Midland Counties Dairy. By this time Stevens Brothers had

been sold to Leo Davenport and he offered to share the premises

with the screw company. Later in 1973 they moved across the road

and sub-contracted much of their work to Leo’s company.

By the 1990s the screw company was

experiencing difficulties, with several of their customers going

into receivership. Jim and Joan decided to concentrate on a

reduced customer base and work towards retirement.

|

In 1991 Jim and Joan decided to retire and close

the Retreat Street factory. After discussion with one of their

main customers Rothley Tube Limited, it was decided that instead

of disposing of all of the machinery, certain items could be

retained and a small machine shop set up on Rothley's site. Jim

would continue, and still continues to produce samples and

machined items, retaining the Stevens Screw Company, which will

exist until Jim decides to call it a day.

I would like to thank Jim and Joan Stevens and the late Geoff Stevens

for their help in producing this history.

|

|

Return to the previous page |

|

|